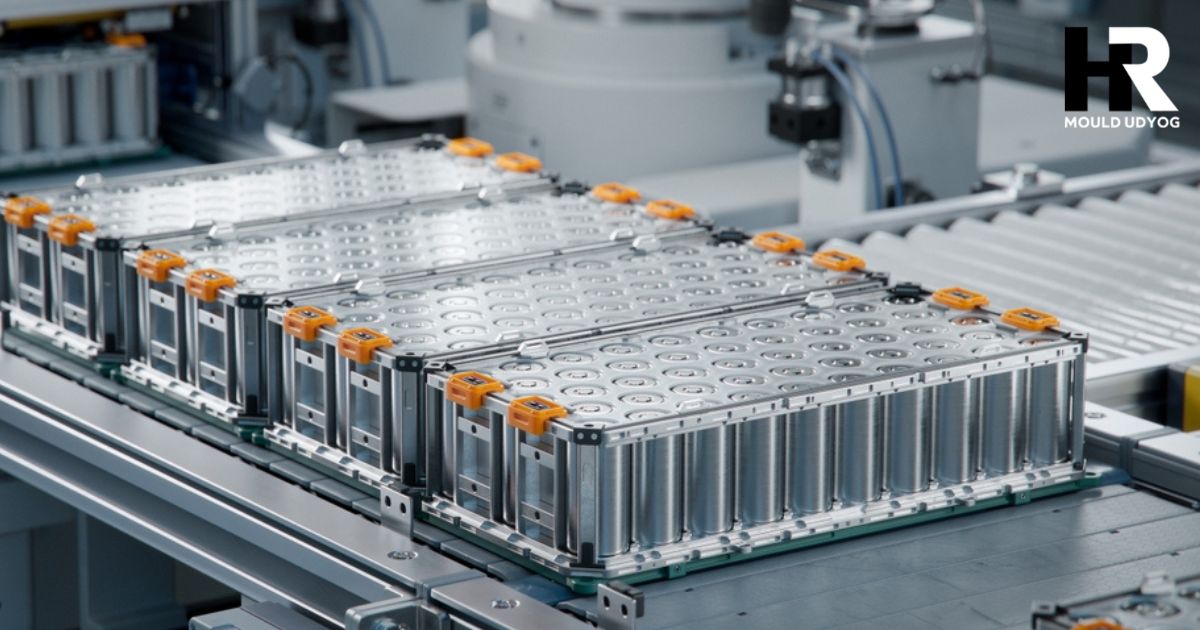

When it comes to battery manufacturing, selecting the right battery container is just as important as choosing the right battery cells. The quality and durability of the container directly impact the overall performance and longevity of the battery. HR Mould Udyog, a Leading Battery Container Manufacturer, understands the critical role that battery containers play in the battery production process. In this blog, we will explore the essential features to consider when choosing the right battery container for your manufacturing needs.

1. Durability

The first and most crucial factor when selecting a battery container is its durability. A high-quality battery container should withstand the wear and tear associated with manufacturing, transportation, and use. HR Mould Udyog’s containers are designed with exceptional durability, ensuring that they can handle the rigors of battery manufacturing and ensure the integrity of the internal battery components.

2. Strength

Strength is another key feature that determines how well a battery container will perform in high-stress conditions. Strong battery containers provide additional protection to the internal components, preventing any damage from external shocks or impacts. Being a Leading Battery Container Manufacturer, HR Mould Udyog’s containers are designed to be exceptionally strong, providing unmatched protection to your battery.

3. High Density

A high-density battery container helps to keep the internal components securely in place. It prevents movement or misalignment of the battery cells, which can result in malfunction or inefficiency. The higher the density, the more resistant the container is to deformation and damage. HR Mould Udyog’s battery containers offer high-density construction, enhancing the stability of the battery.

4. Lightweight

While strength and durability are important, the container should also be lightweight. Heavy battery containers can make the battery system cumbersome, especially for portable applications. HR Mould Udyog’s battery containers offer the perfect balance of strength and lightweight construction, making them suitable for various battery designs.

5. High Impact Resistance

Batteries can be exposed to various impacts during their use, and the container must protect the internal components from damage. A high-impact-resistant container ensures that the battery can withstand external forces without compromising its integrity. HR Mould Udyog’s containers have superior impact resistance, making them perfect for high-performance batteries.

6. High-Quality UV Masterbatches

The material used to make the battery container is important for its overall longevity and performance. HR Mould Udyog’s containers are made using high-quality UV masterbatches, which ensure that the containers can withstand prolonged exposure to sunlight without degrading. This helps in maintaining the aesthetics and functionality of the container for a long period.

7. Cold Forged Lead Bush

HR Mould Udyog’s battery containers feature cold-forged lead bushings, ensuring an enhanced level of strength and a better electrical connection. This feature prevents leakage, improves the battery’s efficiency, and provides excellent protection against environmental factors that could potentially affect battery performance.

8. Excellent Finish

The finish of the battery container is not just about looks, it plays a key role in the overall durability. HR Mould Udyog ensures that every battery container undergoes strict finishing processes, providing a smooth, flawless surface that is resistant to wear and tear. The excellent finish also minimizes the chances of the container corroding or degrading over time.

9. Heat Resistance

High-quality battery containers must also have heat resistance capabilities. Excess heat can cause damage to the internal components of the battery, affecting its overall performance. HR Mould Udyog’s containers are engineered with heat resistance features, ensuring they can withstand high temperatures without losing their shape or integrity.

10. Less Water Loss

Water loss can impact the performance of a battery, particularly in high-temperature environments. HR Mould Udyog’s containers are designed to minimize water loss, ensuring that the battery’s electrolyte levels remain consistent, leading to more reliable and efficient performance.

11. No Cracking or Breaking During Hole Punching

During manufacturing, some battery containers require hole punching. Poorly designed containers can crack or break during this process, compromising their integrity. HR Mould Udyog’s containers are specifically designed to resist cracking or breaking while hole punching, ensuring a smooth production process and avoiding unnecessary wastage.

12. Retain Original Color for a Longer Period

The appearance of the battery container is also important, especially if the battery is visible to customers. HR Mould Udyog’s containers retain their original color for a long period, thanks to the use of high-quality materials that resist fading, ensuring that your battery maintains its professional look for longer.

Conclusion

Choosing the right battery container is crucial to ensuring the long-term performance, efficiency, and safety of your batteries. HR Mould Udyog, a Leading Battery Container Manufacturer, offers containers that combine durability, strength, lightweight design, and high impact resistance. With features such as UV protection, heat resistance, and cold-forged lead bushings, their containers are built to meet the demands of modern battery manufacturing.

Ready to optimize your battery manufacturing with high-quality containers? Contact HR Mould Udyog today to explore our range of top-of-the-line battery containers. Whether you’re looking for customization options or standard designs, we’ve got the perfect solution for you. Reach out now for more details!