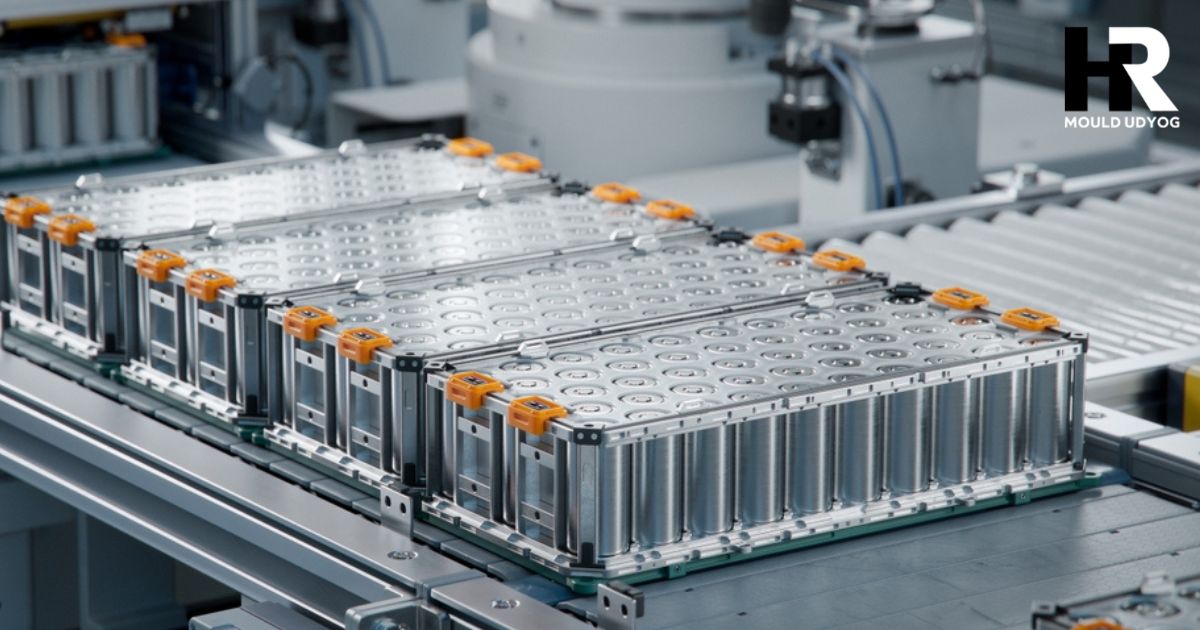

Batteries are an essential part of many devices, from smartphones to vehicles. To ensure they last longer and perform efficiently, manufacturers have to pay attention to various components of the battery. One such crucial part is the side packing jali, a material that helps protect the battery’s internal structure while improving its performance. HR Mould Udyog, a leading side packing jali manufacturer in Delhi, has designed high-quality side packingjali that plays a key role in enhancing battery cell life and performance.

What is Battery Packing Jali?

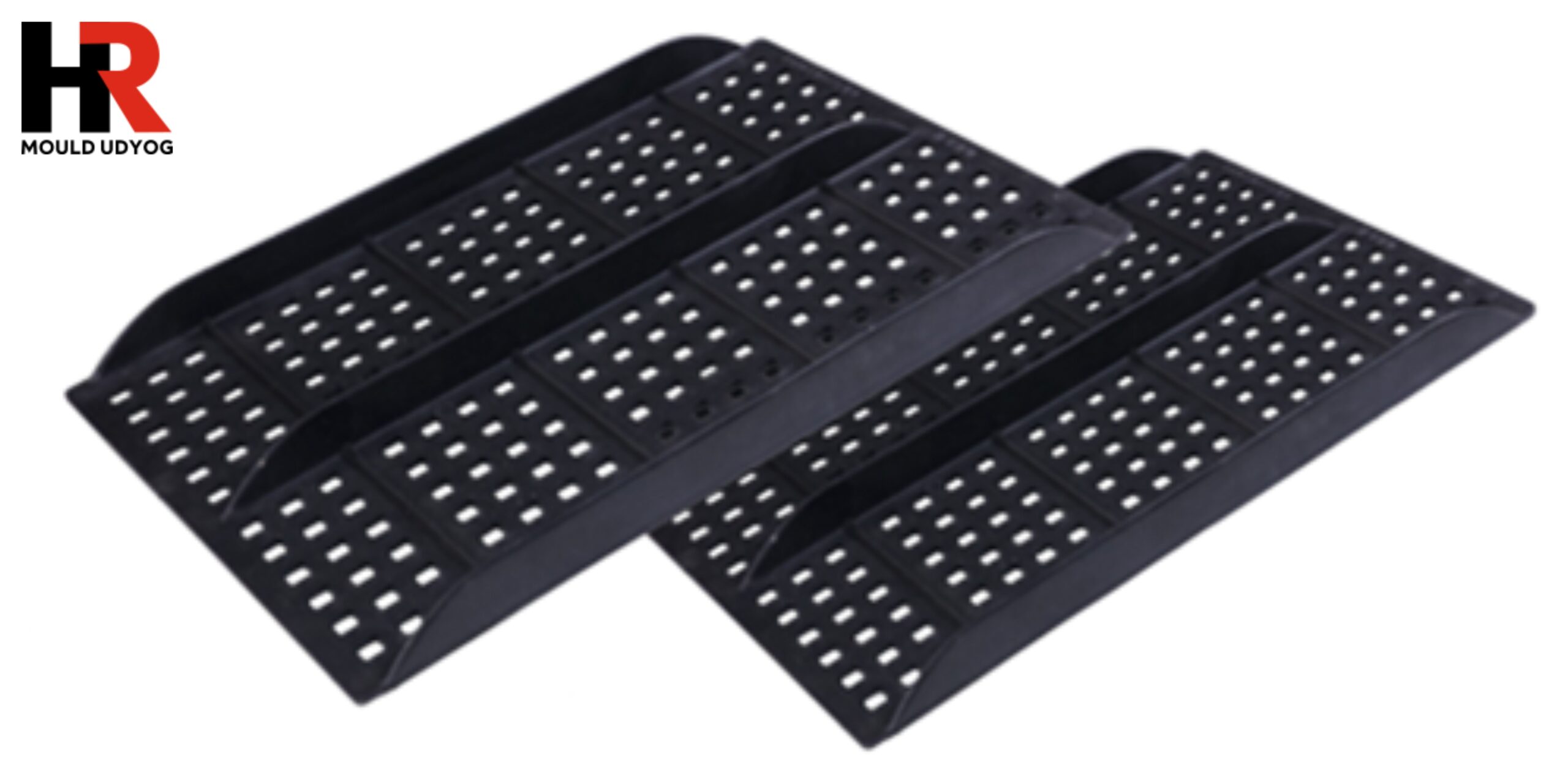

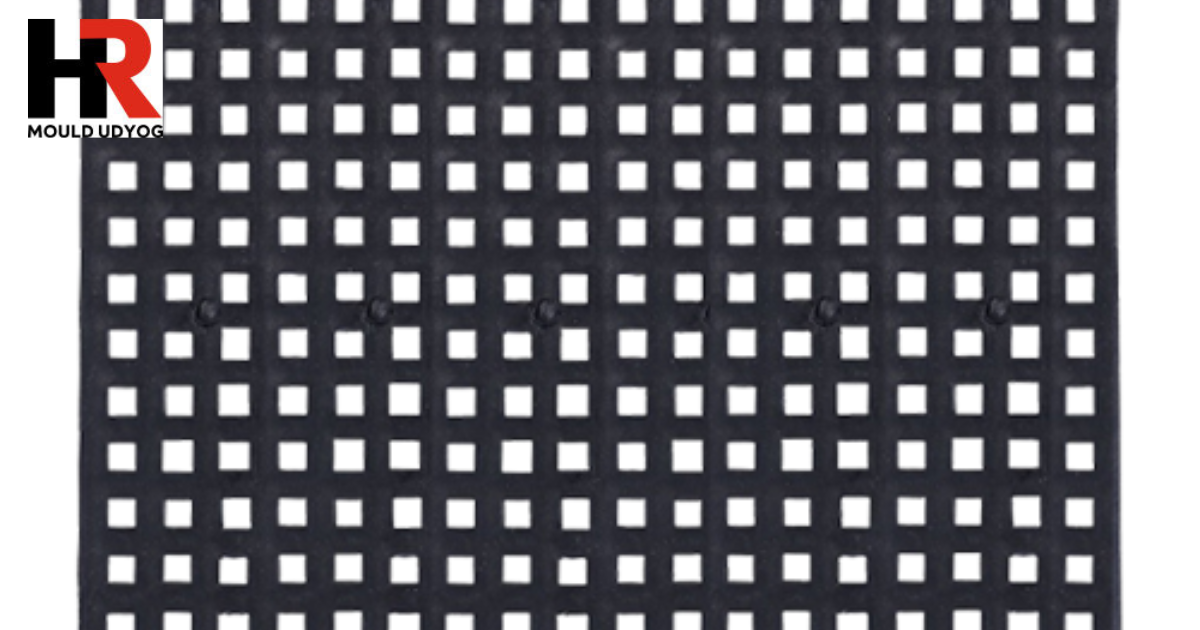

Battery packing jali refers to the grid-like structure that surrounds the battery cell’s core components. It is made from durable materials and helps keep the battery components secure. The packing jali also aids in managing heat dissipation, which is vital for the battery’s longevity.

How Does Battery Packing Jali Enhance Battery Life?

1. Heat Regulation: One of the main reasons for battery degradation is excessive heat buildup. HR Mould Udyog’s battery packing jali is designed to ensure optimal airflow around the battery, reducing the risk of overheating. This helps in maintaining the battery’s efficiency for a longer period, directly contributing to enhanced battery life.

2. Improved Durability: The robust design of the battery packing jali from HR Mould Udyog protects the internal components of the battery from external shocks and vibrations. This ensures that the battery remains in top condition, even in challenging conditions, which results in longer-lasting performance.

3. Better Efficiency: The efficient design of the battery packing jali by HR Mould Udyog aids in maintaining the battery’s performance by preventing any unnecessary energy loss. This leads to a more stable and reliable battery performance, which is vital for devices and vehicles that depend on consistent energy supply.

4. Customizable Designs: As a top side packing jali manufacturer in Delhi, HR Mould Udyog offers customizable packing jali that suits the specific needs of different battery types. Whether it’s for small batteries or large industrial ones, their packing jali ensures that each battery performs optimally according to its design.

Why Choose HR Mould Udyog as Your Battery Packing Jali Manufacturer in Delhi?

HR Mould Udyog has earned a reputation as a trusted side packing jali manufacturer in Delhi due to its commitment to quality and innovation. Their packing jali is crafted with precision to meet the highest standards. Here are a few reasons to choose them:

1. Expertise and Experience: With years of experience in the industry, they understand the unique needs of battery manufacturers and provide solutions that improve battery performance.

2. Top-Quality Materials: HR Mould Udyog uses the best materials to ensure that their packing jali is both durable and efficient.

3. Custom Solutions: They offer customized solutions to cater to the specific requirements of their clients, ensuring perfect compatibility with various types of batteries.

4.Get new designs within 1 week of requirement:

HR Mould Udyog delivers customized designs within just one week of receiving the requirement, ensuring fast and efficient solutions for battery manufacturers in need of timely production without compromising on quality.

Conclusion

The battery packing jali plays a crucial role in enhancing battery life and performance. HR Mould Udyog, as a leading side packing jali manufacturer in Delhi, provides high-quality packing jali solutions that ensure better heat regulation, durability, safety, and overall efficiency. Choosing HR Mould Udyog guarantees you top-notch products that will help extend the life of your batteries while maintaining their optimal performance.

If you’re looking for a reliable side packing jali manufacturer in Delhi, HR Mould Udyog is your go-to choice.