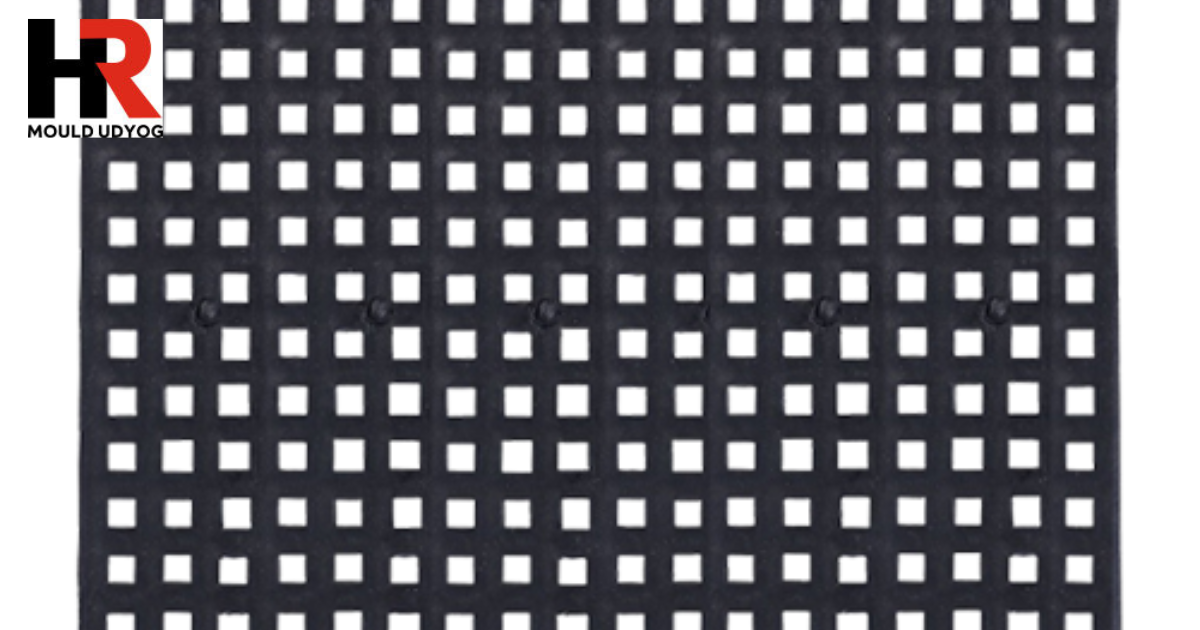

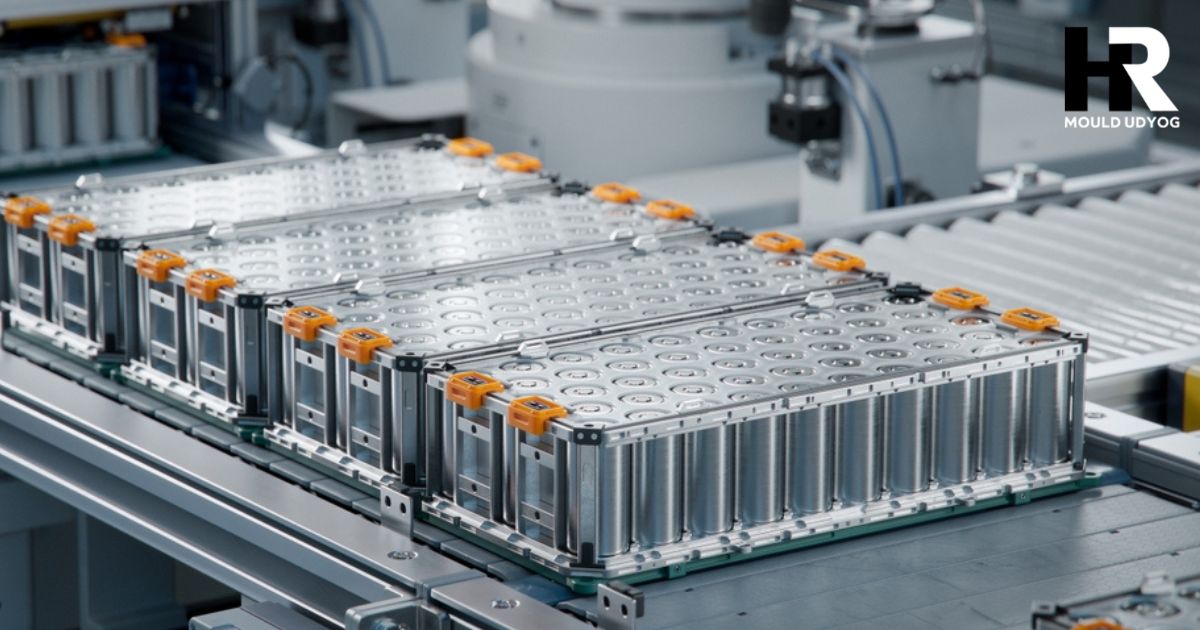

In the dynamic world of battery manufacturing, the importance of quality packaging cannot be overstated. A reliable and durable side packing solution is crucial for ensuring the safety and integrity of batteries during storage and transportation. HR Mould Udyog has established itself as a leading battery Side Packing Jali Manufacturer, providing high-quality products that meet the diverse needs of the battery industry. Here are several compelling reasons why choosing HR Mould Udyog for your side packing jali needs is a smart decision.

1. Superior Quality

At HR Mould Udyog, quality is the cornerstone of our manufacturing process. We utilize high-grade raw materials, German technology and advanced manufacturing techniques to produce side packing jali that adheres to international quality standards. Our commitment to quality ensures that each product undergoes rigorous testing, providing our clients with reliable and durable packing solutions. By choosing HR Mould Udyog, you can rest assured that your batteries are well-protected during transit and storage.

2. Customized Solutions

Every battery manufacturer has unique requirements, and HR Mould Udyog understands this need for customization. We offer a wide range of side packing jali designs and specifications tailored to fit various battery sizes and shapes. Our team of experts collaborates closely with clients to understand their specific needs, ensuring that our products provide the best possible fit and protection for their batteries. This level of customization helps prevent damage during handling and transportation.

3. Enhanced Protection

HR Mould Udyog’s side packing jali is engineered to provide superior protection against impacts and vibrations in the battery cell. Additionally, our packing solutions are designed to allow proper ventilation, which is essential for maintaining the integrity of battery performance. With HR Mould Udyog’s products, you can trust that your batteries will deliver optimum performance.

4. Timely Delivery

In the fast-paced battery manufacturing industry, timely delivery is crucial. HR Mould Udyog recognizes the importance of meeting deadlines and ensures that orders are processed and delivered promptly. Our streamlined production processes and efficient logistics management enable us to fulfill orders quickly, helping our clients maintain their production schedules without delays. When you choose HR Mould, you choose a partner that prioritizes your time and operational efficiency.

5. Low Iron Content with Verified Test Reports

HR Mould Udyog’s side packing jali features low iron content, making it an excellent choice for battery manufacturers concerned about corrosion and performance. The reduced iron content not only enhances the durability but also minimizes the risk of degradation that can occur with traditional materials. We provide verified test reports that validate our low iron specifications, assuring clients of the quality and reliability of our products. This transparency demonstrates our commitment to delivering superior side packing jali that offer superior performance.

6. Strong Customer Support

At HR Mould Udyog, we believe that customer satisfaction is paramount. Our dedicated customer support team is always available to address inquiries, provide assistance, and offer guidance throughout the purchasing process. We value our clients’ feedback and continuously strive to improve our products and services based on their needs and suggestions. Choosing HR Mould Udyog means gaining a reliable partner that prioritizes your success.

Conclusion

In conclusion, HR Mould Udyog is the premier battery side packing jali manufacturer, offering superior quality, customization, and protection for your battery products. With our commitment to cost-effectiveness, sustainability, and timely delivery, we have established ourselves as a trusted partner for battery manufacturers looking for reliable packing solutions. By choosing HR Mould for your side packing jali needs, you are making a smart investment in the safety and integrity of your batteries.